DIAMOND PULSE-TECH

A unique and revolutionary technology

DIAMOND PULSE-TECH features breakthrough innovations, developed from scratch, across the entire drilling system.

- DPT technology with micro-percussion.

- DPT anti-vibration technology.

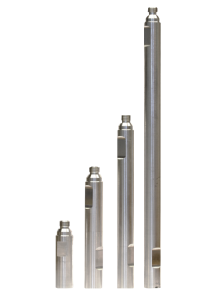

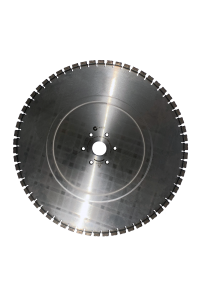

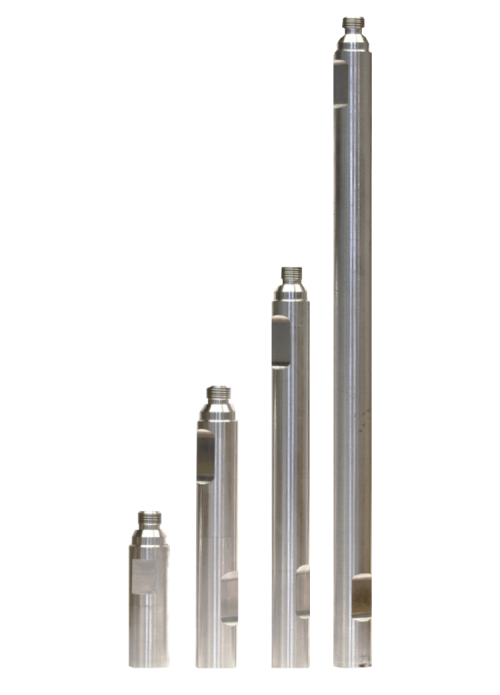

- DPT innovative state-of-the-art core bits.

All components of the DIAMOND PULSE-TECH system work in synergy to enable advanced hybrid drilling.

Advanced hybrid core drill with micro-percussion

- Allows to choose between 2 advanced drilling options:

- advanced dry drilling: for a clean and faster drilling, in any environment.

- advanced wet drilling: for a faster drilling.

- Features the innovative DPT technology with micro-percussion, developed by CARDI, which provides a super-fast soft hammering effect – 10-29k hits/min on load – and maintains the segment sharped, clear from dust and debris, in all materials and conditions.

- Is equipped with the reliable, robust and powerful CARDI motors, delivering max power / current up to 4,600 W / 22 A, respectively.

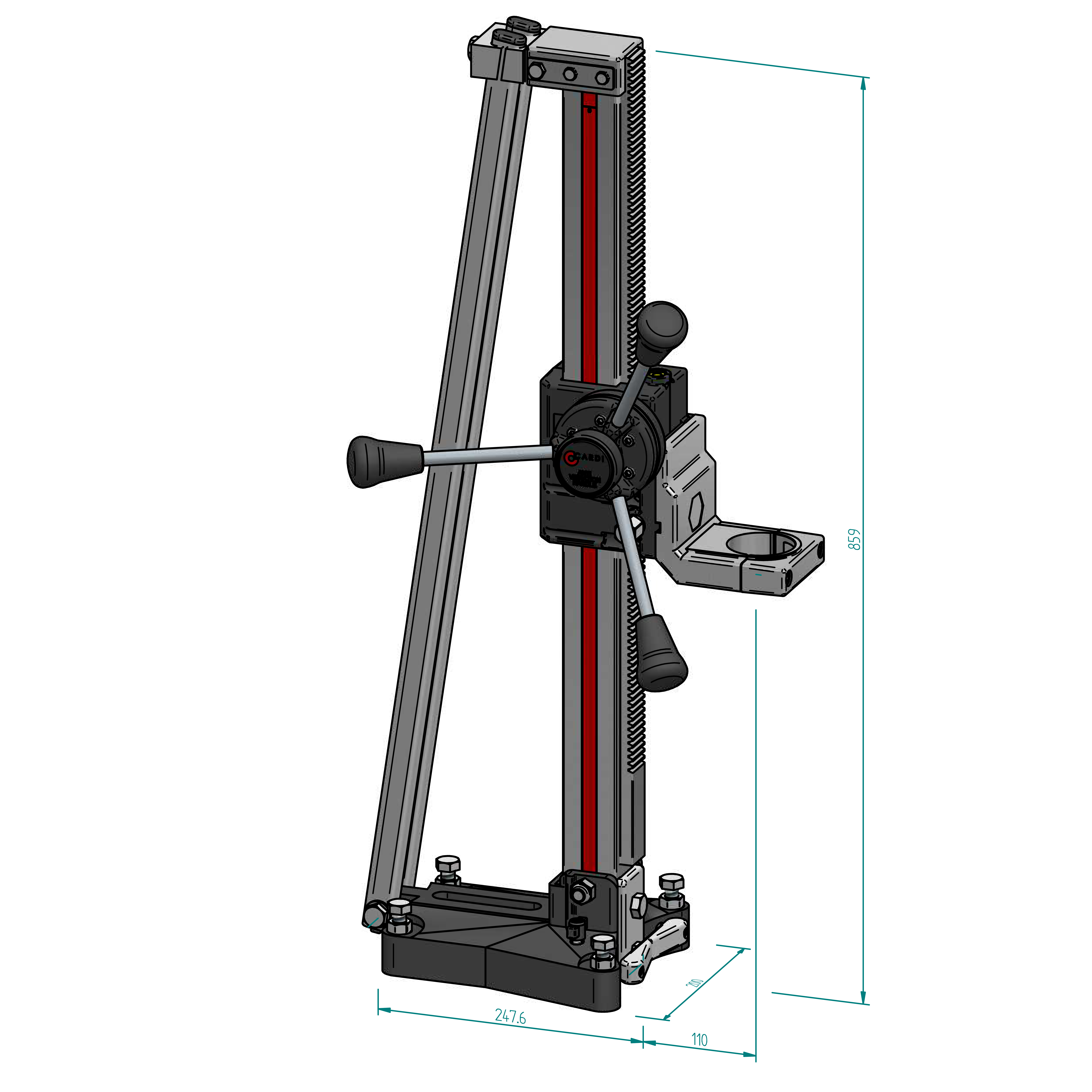

Core drill stand (rig) with anti-vibration technology

- Features a new technology, developed by CARDI, that reduces vibrations by 50%, providing increased safety for the user and allowing longer working hours.

- Delivers a stable and efficient drilling performance, thanks to the reinforced structural design and materials used in all CARDI stands (rigs), while maintaining a compact size to ease transportability.

Advantages of the advanced dry

Work cleanly

- Drill cleanly, keep your site spotless: no water / slurry.

- Do not worry about the water connection.

- Work in every environment (e.g., finished interiors).

Work faster

- Avoid site set-up: no water containment / connection.

- Drill faster, on all materials, vs. standard wet drilling.

- Avoid site clean-up: no water / slurry cleaning and disposal.

Reduce waste

- Get less waste: dust, no water and no slurry.

- Get a simpler, useful waste.

Avoid damages

- Avoid risk and costs of property damages due to water leakages.

Advantages of the advanced wet

Work faster

- Higher drilling speed, on all materials, vs. standard wet drilling.

Work as usual

- Keep on working with water when / if you prefer, as you are used to, while getting an unmatched drilling performance.

Applications & Users

Applications:

- Drillings for HVAC installation

- Drillings for networks (e.g., internet, security systems, fire protection systems) installation

- Drillings for anchors installation

- Drillings for chimneys installation

- Drillings for guardrails and fences installation

- Drillings of marble and stone slabs

- Sampling of cores

- Manhole / round openings

- Stitch drilling

Users:

- Plumber

- Electrician

- Installer (e.g., HVAC, networks, anchors, chimneys, guardrails and fences)

- Stonemason

- Landscaper / gardener

- Company specialized in materials’ testing

- Construction company / general contractor

- Professional drilling and cutting company

- Demolition expert

Get in touch

Do you need any information or help?

Please fill the form below or email us at info@cardi.biz.

Our team is here to help you.